Product Description

Pallets can be lifted easily, quickly and safely using a vacuum tube lifter.

Lifting systems based on vacuum technology are often used in industry where fast repetitive handling of heavy loads is required. Using a single power medium – vacuum, to grip and lift heavy or awkward loads. To lift a pallet, the operator simply inserts the pallet forks under the top boards of the pallet. Lightweight modern designs are used throughout the range.

Vacuum Tube Lifter – Features

|

|

Our solutions are backed by top-level engineering, project and quality management including validation.

How a Vacuum Tube Lifter Works

- Grip – Simply land on a product to grip it

- Lift – Gently pull up the control lever to lift

- Lower – Gently press down the control lever to lower

- Release – Push the lever down fully, and tilt the handle to release the load

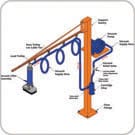

Typical Layout of a Vacuum Tube Lifter & Support System Options

Vacuum Tube Lifters may be suspended from a variety of crane styles to allow the operator to cover the area where products to be lifted are handled. The most common cranes used are pictured below, wall or ceiling mounted versions of all of these cranes are also used when existing structures are suitable for supporting the crane.